Design research into the possibilities of 3D concrete printed facades

Together with TU Eindhoven’s Department of Architecture and Engineering, led by Prof Juliette Bekkering and the specialised 3DCprint company Vertico, Neutelings Riedijk Architects has dived into the possibilities of 3D printing concrete. The research focused primarily on the technical feasibility of double-curved facades with filigree infill, a visual language as has been applied more often by Neutelings Riedijk Architects.

Circular moulds made of sand

For a year, all parties involved investigated the architectural possibilities of 3DConcrete Printing (3DCP) on circular double-curved moulds. Central to this research was that both the architectural possibilities were explored, i.e. how the typical properties of the 3DCP technique can lead to an appealing image and a new expression in architecture, and the technique was developed to actually make it. Robots were used to make circular moulds of sand, formed into a double-curved bed on which the concrete elements were printed.

From raw material to fascinating expression

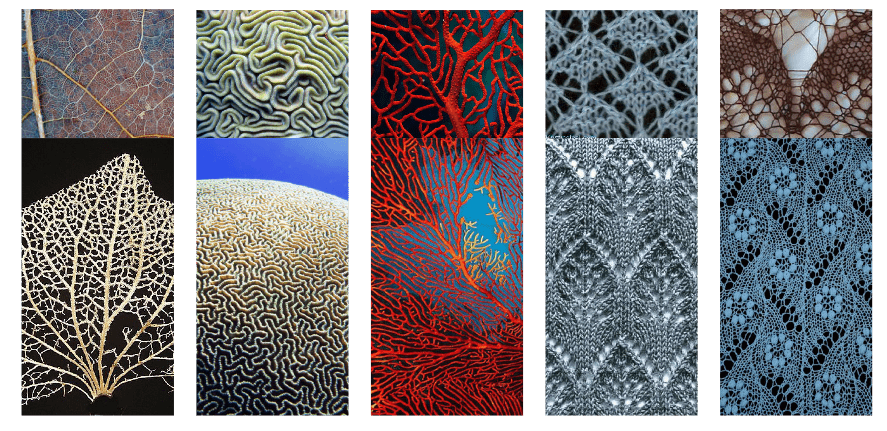

With the 3DCP, unique patterns and decorations can be easily realised without labour-intensive processes and waste. We were fascinated by the possibility of printing filigree patterns, concrete-like lacework that can be used to create facades and translucent interior walls. A whole range of new architectural expressions can be created using this technique.

Methodology for circular construction

The research focuses on the need for circular construction, reducing the use of raw materials for concrete formwork and developing optimised strategies for pouring material to reduce the use of concrete. The research investigates the use of robotically formed sand formwork, through which it avoids the need for wooden scaffolding, plastic or foam-based formwork for pouring concrete.

The research will be presented in detail during Dutch Design Week 2023 in Eindhoven.

CREDITS

Funding Body:

Dutch Research Council (NWO): KIEM-CE Grant

2022 — 2023

Team:

Eindhoven University of Technology, faculty of the built environment — Chair of Architectural Design and Engineering ADE: Prof. Juliette Bekkering, Architect, Assist. Prof. Cristina Nan (architect and computational design and digital fabrication specialist)

Neuteling Riedijk Architects: Michiel Riedijk, Founder; Chaoyu Huang, Aleksandra Gwardiak, Architects

Vertico — 3D Concrete Printing Specialists: Volker Ruitinga, Founder; Kees Leemeijer, Robotic Fabrication Engineer; Orestis Pavlidis, Robotic Fabrication Engineer

Researcher: Alessio Vigorito, structural engineer

Supported by

Betonhuis, Cindy Vissering